Customizable IP68 aluminum enclosures

IP68 - 2 m / 60 min

Our enclosures offer unrivalled protection against water and dust, guaranteeing optimum performance even underwater in accordance with IEC 60529.

Anti-corrosion

Tested for 1,000 hours in a salt spray environment in accordance with ASTM B117, our enclosures are corrosion-resistant, ensuring exceptional durability.

Shock-resistant

Thanks to their high-pressure die-cast AlSi12 structure and robust mechanical design, efaboxes withstand stresses of up to 7 J in accordance with EN60079.

Customizable

Customize your enclosures with our color, logo and drilling pattern options. Electronic assembly is also our specialty.

Design, produce, deliver : an integrated offer

From 3D design to finished product, efa controls all industrial stages in-house. Our engineers develop your parts, produce prototypes, and optimize weight and performance using advanced simulations (FEM, thermal flow, molding). In our workshops, we design and manufacture all the tooling required for die-casting: moulds, clamping devices, cutting tools – nothing is outsourced.

Our fleet of presses (80 to 400 t, up to 800 t via partners) is equipped with the most advanced technologies (TFI, Parashot, PLC), to guarantee parts from 2 g to 5.5 kg with flawless surfaces and optimum mechanical properties. Loading robots, automated injection, conveyors: our process is fully controlled.

Each part is then deburred, machined (CNC ± 0.05 mm), polished and coated on our 9-bath powder line. Rigorous in-house quality control (optical CMM, ASTM tests, Cp/CpK) guarantees total reliability, even in extreme conditions.

A customized solution with our accessories

Our partner for cable glands: Wiska

To guarantee a perfect seal right to the heart of your Efaboxes, we integrate Wiska cable glands. Available in brass, stainless steel or polyamide, they share the same clamping range and come in metric, PG or NPT threads.

The 4-in-1 principle (cover, sealing insert, optional EMC module, connector) simplifies assembly: a single tool is all that’s needed, the torque remains reproducible, and the pull-out resistance is certified to DIN EN 62444. Each variant achieves IP 68 and IP 69K ratings, ensuring a reliable barrier under 2 m immersion as well as high-pressure jets, and remains operational from -60°C to +100°C.

Multiple inserts, reducers or venting membranes offer multi-line wiring, internal pressure compensation or 360° shielding against EMC interference. Combined with our aluminum enclosures, these accessories make up a turnkey solution: single delivery, factory IP testing, RoHS/REACH compliance and documentation ready for your quality audits.

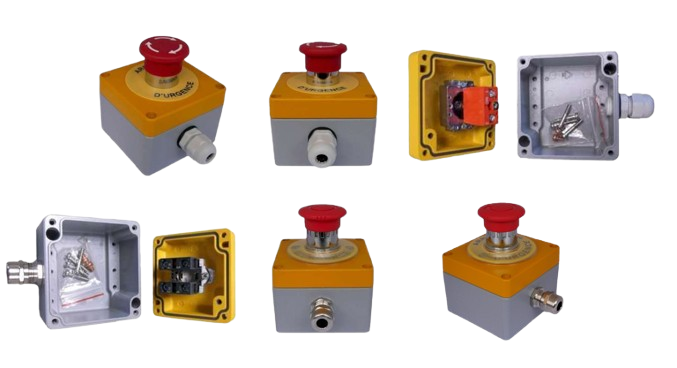

Emergency stop: Schneider and Teknic

Whatever type of emergency stop your project requires, it can be made to order in quantities ranging from 10 to 10,000.

Housed in an efabox die-cast enclosure painted gray RAL 7001, this emergency stop box combines safety, robustness and rapid assembly.

The yellow RAL 1004 cover accommodates a 40 mm dia. Teknic mushroom button with rotary release, fitted with a positively driven 1 NC contact capable of switching 10 A at 600 V AC. Thanks to a compressed silicone gasket and captive stainless steel screws, the unit achieves IP 65 and IP 69K ratings: it remains watertight both under punctual immersion and during high-pressure cleaning. The IK08-approved body absorbs shocks and resists vibrations for a long time, while the -40°C / +85°C range ensures reliability on mobile machines, outdoor panels or production lines.

A factory-machined M16 × 1.5 thread facilitates installation of a Wiska SPRINT® cable gland, guaranteeing watertightness and strain relief in compliance with DIN EN 62444.

Laser traceability, EN ISO 13850 compliance and over 1,000 hours of salt spray testing complete this ready-to-wire solution, available with NO additive contact option, decompression membrane or customer marking on request.

Complete assembly

Our position as a distributor-integrator enables us to maintain buffer stocks of strategic components, reducing your lead times and optimizing your costs. The know-how we’ve acquired on our Power Distribution Units – up to 800 V and 1500 A – comes in ready-to-plug IP68 enclosures: shielded connectors, fuses, busbars and safety monitoring adapt to both mobile and stationary equipment.

The result is a robust, ASTM-tested, turnkey box that simplifies your assembly lines while ensuring reliable power supply to your machines.